The global shift toward renewable energy has catalyzed a dramatic expansion in the energy manufacturing sector. Wind, solar, and other clean technologies are fueling job creation at a breakneck pace, and with this boom has come a surge in demand for technicians capable of installing, maintaining, and optimizing these systems. To meet this demand, thousands of new workers have pursued and obtained entry-level certifications—marking their official entrance into the industry.

However, this rapid influx of freshly certified technicians, while essential to scaling the renewable energy transition, has exposed a growing imbalance. Many of these new hires possess the theoretical knowledge and baseline skills validated through certification programs, but they often lack the hands-on, job-site experience required to confidently and efficiently operate in real-world settings. As a result, energy manufacturing companies are now grappling with a growing training burden—tasked with bringing these green technicians up to speed without compromising project timelines, safety standards, or production quality.

The Experience Bottleneck

This imbalance between seasoned professionals and newly certified entry-level technicians is becoming increasingly apparent across the energy manufacturing landscape. While it’s undeniably positive to see so many individuals entering the sector, their lack of practical, on-the-ground experience has created mounting pressure on employers. Existing, experienced workers are being asked not only to fulfill their primary roles but also to train and supervise newcomers—often without adequate time or resources.

For many companies, this dynamic creates a bottleneck. Project managers face slowdowns due to inexperience-induced errors or delays, quality assurance teams are stretched thin ensuring compliance, and veteran technicians may experience burnout from the dual responsibility of doing and teaching. While certifications are a great first step, they don’t automatically translate to readiness for the field.

This challenge is compounded by the complexity of modern energy systems. Whether it’s the precision required in turbine blade installation or the intricate diagnostics needed to troubleshoot solar array performance, today’s technicians must have far more than basic knowledge. They need field-hardened skills, decision-making agility, and the ability to operate in dynamic, high-risk environments.

The Need for Advanced, On-the-Job Training

To keep pace with demand and ensure the continued success of renewable projects, companies require scalable training solutions that go beyond certification. Upskilling programs designed to bridge the gap between classroom learning and jobsite execution are no longer a “nice-to-have”—they’re a business necessity.

This is where organizations like STL USA have stepped into the spotlight.

STL USA: Pioneering Upskilling in Energy Manufacturing

STL USA has emerged as a leading force in tackling the technician experience gap head-on. Recognizing the urgency of the situation, the company has developed custom-built training programs specifically designed to move technicians beyond entry-level certification and into confident, capable field roles.

At the core of STL USA’s approach is its deep understanding of both the technical demands of the job and the operational pressures facing energy manufacturers. Rather than offer one-size-fits-all training, STL works directly with companies to create tailored upskilling programs that address real-world challenges, prioritize safety, and accelerate readiness.

A prime example of this forward-thinking approach is the Total Wind Program, developed in partnership with the Distributed Wind Power Association (DWPA). This program is engineered to prepare wind technicians not just to meet the minimum standards of certification but to excel in live environments. Through a combination of immersive practical training, mentorship, and scenario-based problem-solving, Total Wind enables new hires to rapidly gain the experience they need to become productive members of the workforce.

Why It Works

The strength of STL USA’s programs lies in their real-world relevance. Technicians are trained on the actual equipment they’ll encounter in the field. They learn in environments that simulate the physical and operational realities of modern energy manufacturing. And perhaps most importantly, they are mentored by seasoned professionals who translate theory into practice—ensuring that trainees internalize safety protocols, troubleshooting logic, and teamwork essentials.

This hands-on, situational learning approach has proven to be far more effective than passive classroom instruction alone. It closes the loop between certification and capability, producing technicians who are not only certified but also competent.

Benefits for Energy Manufacturers

For energy companies, partnering with STL USA is more than just a training investment—it’s a strategic move to protect and enhance operational performance. Upskilled technicians contribute to:

Faster project turnaround times

Improved safety records

Reduced reliance on overstretched senior personnel

Greater workforce retention and satisfaction

In a sector where margins are tight and timelines are aggressive, these benefits make a measurable difference.

Building the Future Workforce

The energy transition is not slowing down, and neither is the need for skilled labor. With projections indicating continued growth across wind, solar, and energy storage, the industry must double down on training strategies that produce field-ready professionals—not just paper-certified ones.

STL USA is leading the way in this essential evolution. By working in tandem with companies and industry associations like the DWPA, they are helping to build a stronger, more resilient workforce—capable of meeting today’s renewable energy challenges and tomorrow’s opportunities.

In a world powered increasingly by clean energy, moving beyond entry-level certification isn’t just about individual success—it’s about ensuring the entire industry thrives.

Want to learn more about Total Wind Treaining?

Click the button to find out more

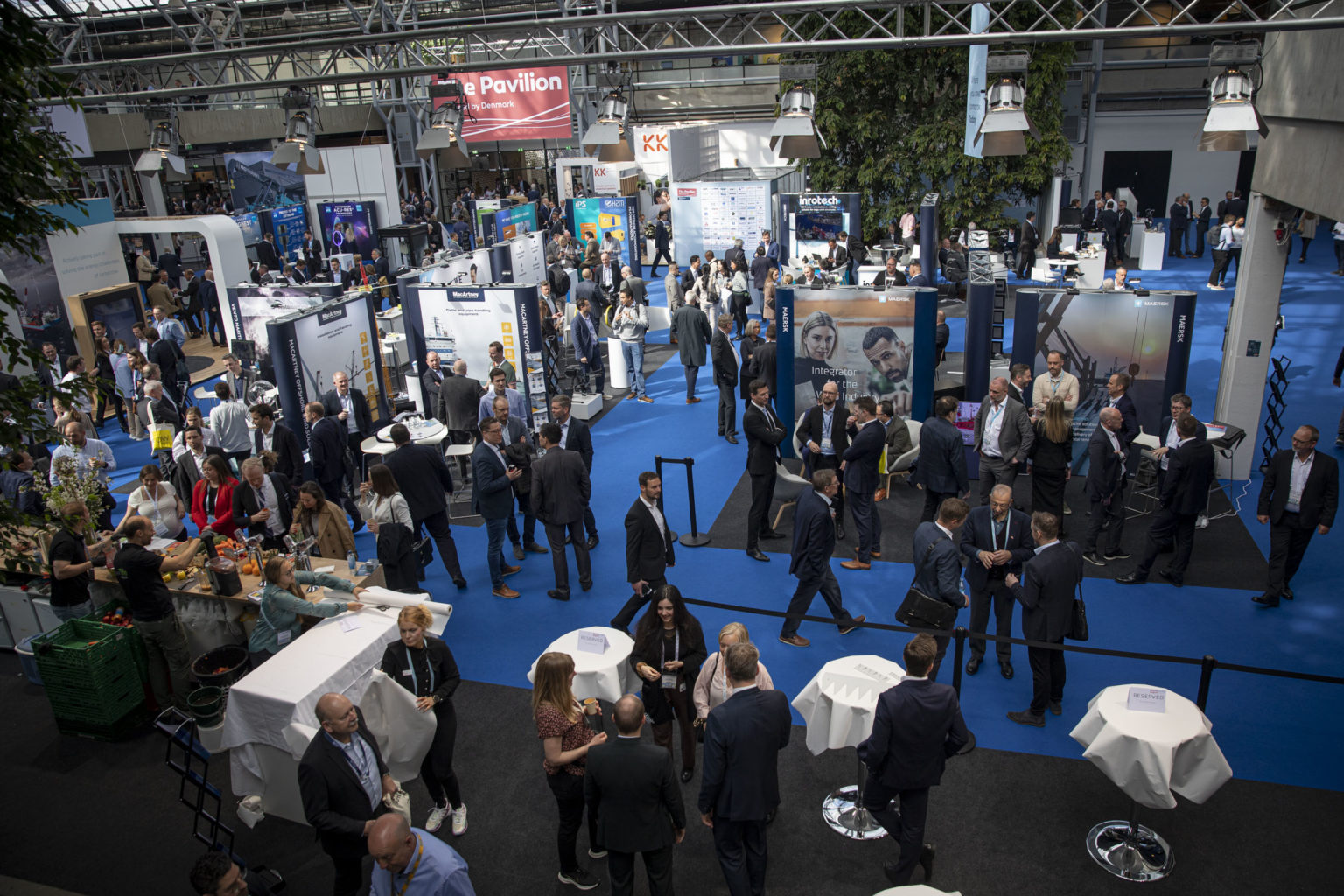

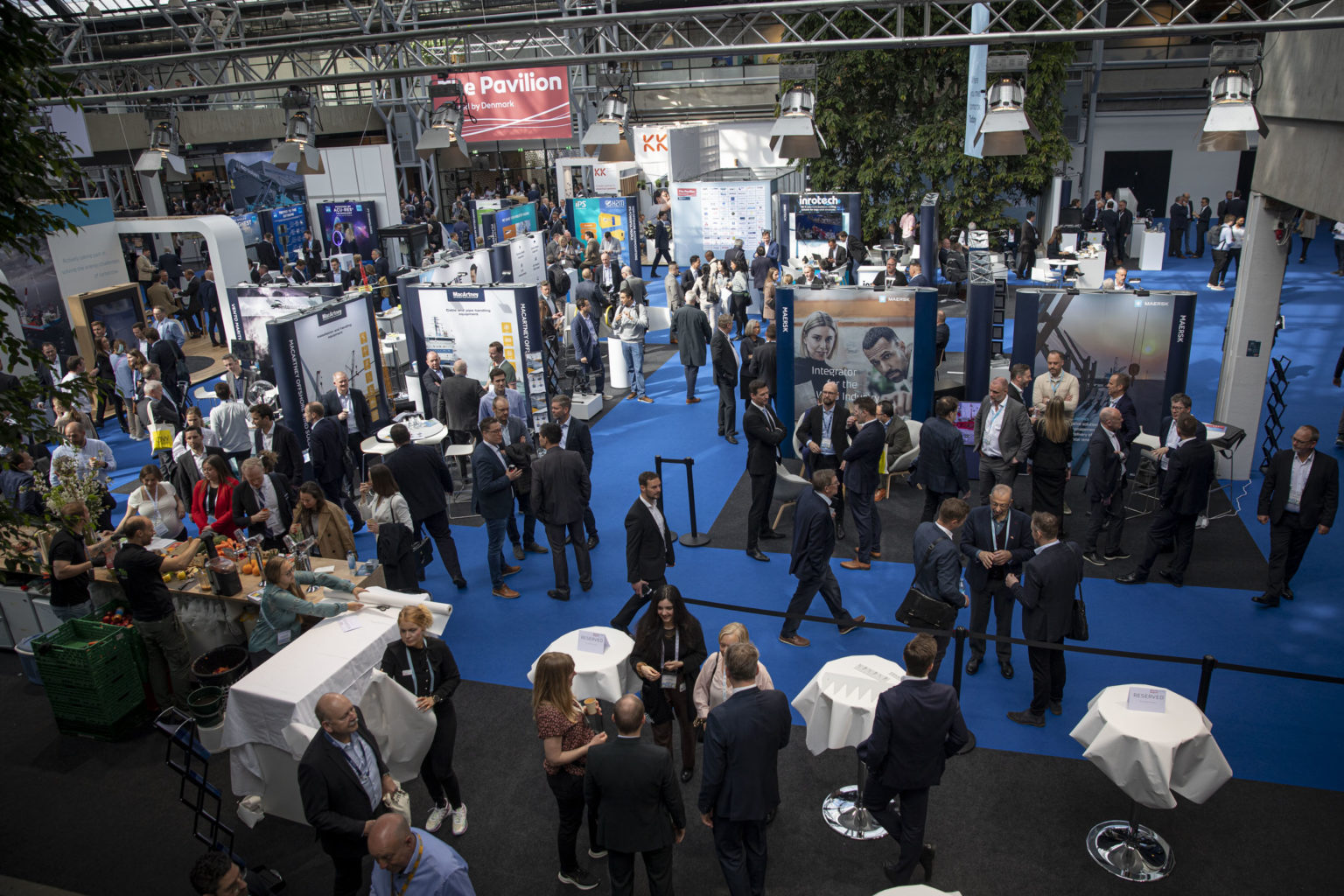

Where to Find Us: STAND 500 OMS 2025, Nashville, March 3-5

Where to Find Us: STAND 500 OMS 2025, Nashville, March 3-5 Book a Meeting with Our Team:

Book a Meeting with Our Team: